Tool & Die Makers

Metal Press Tooling In Boksburg

Paxprecision (Pty) Ltd offers top-tier metal press tooling in Boksburg. With over 20 years of experience, we deliver high-quality engineering solutions and precise manufacturing capabilities.

Precision Toolmaking

Specializing in metal press tooling and custom moulds, we achieve exacting precision in every project.

Advanced Technology

Equipped with the latest CNC and EDM technology, we deliver superior results and efficient production.

Reliable Delivery

Meeting deadlines without compromising quality, ensuring your projects are completed on time.

Our skilled team brings two decades of experience, consistently providing high-quality engineering solutions.

Projects Completed

Precision Crafted, Results Delivered

At Paxprecision, we bring two decades of expertise in toolmaking and precision engineering. From CNC machining to metal press tooling, we provide high-quality solutions that meet the industry’s most demanding standards.

Moreover, our commitment to innovation and quality ensures that each project is delivered with accuracy and excellence.

“Exceptional quality and attention to detail. Paxprecision always delivers on time and beyond expectations. “

Innovating with Precision, Engineering with Purpose

At Paxprecision, we turn complex engineering challenges into streamlined solutions. From concept to completion, we deliver high-quality tooling services that drive exceptional results and exceed expectations.

Our Vision

Shaping the Future of Precision Engineering Description: Our vision is to lead the industry as a trusted name in innovative toolmaking and reliable engineering services, setting the standard for excellence in South Africa.

Our Mission

Excellence in Every Cut and Design Description: Our mission is to deliver unmatched craftsmanship and cutting-edge solutions, providing our clients with reliable, high-quality products, all backed by 20 years of experience.

"Crafted with passion, engineered for excellence""

Setting The Standard

Engineering Solutions Tailored for Precision

CNC Milling & CAD Design

Precision 3-axis CNC milling combined with full CAD design and 3D printing. We expertly machine complex parts, visualize designs, and offer rapid prototyping for accurate and efficient production.

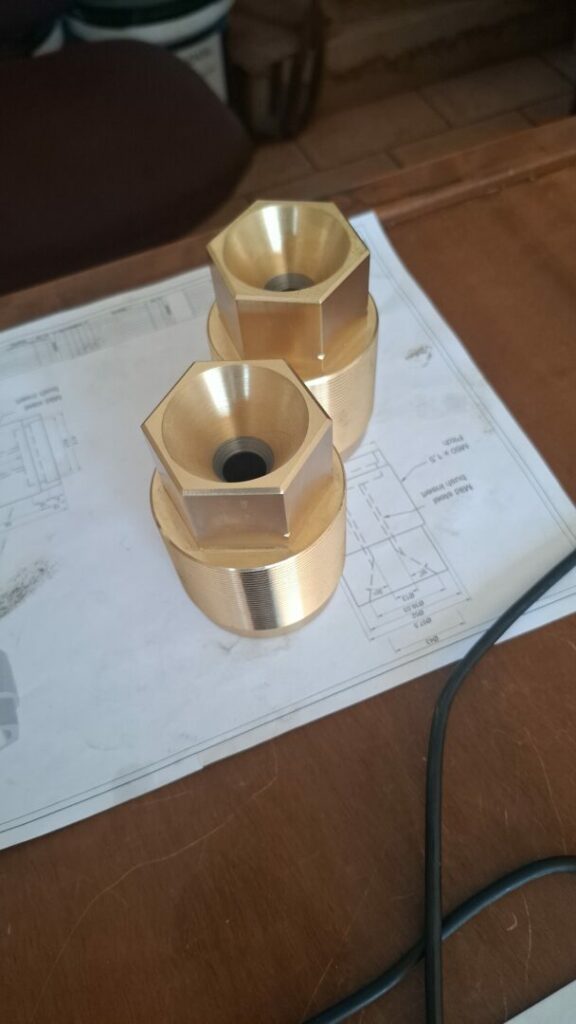

CNC Turning

Our CNC turning services handle intricate round components with precision, using automated lathes for consistent quality, whether it’s for one-off pieces or high-volume production requirements.

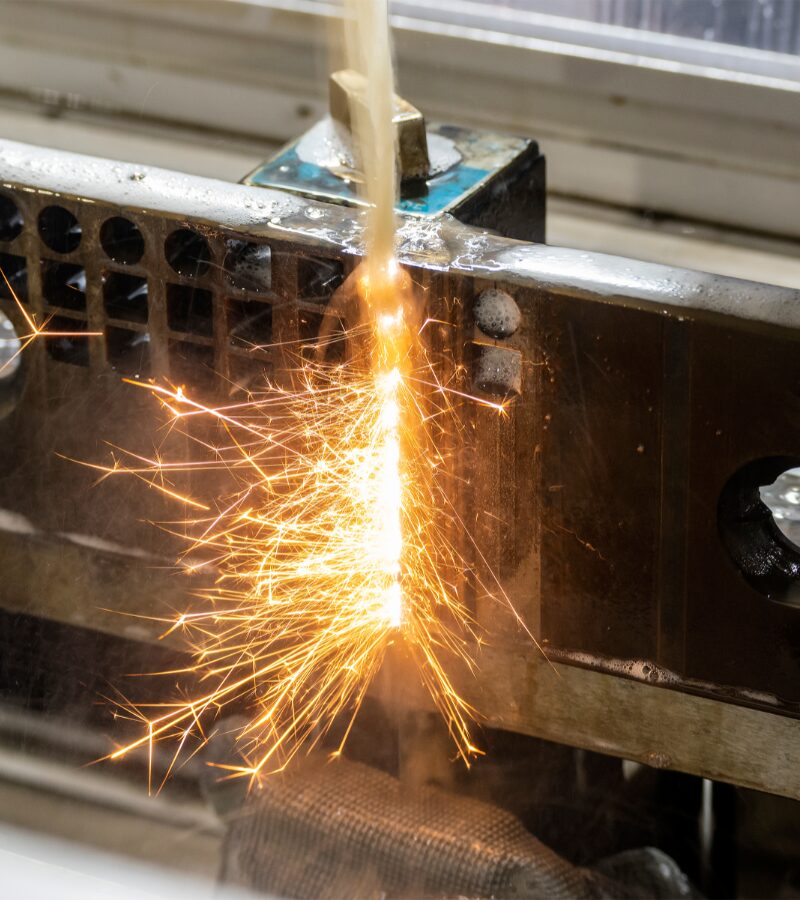

EDM Spark Eroding

EDM spark eroding uses electrical discharges to shape intricate details in conductive materials, making it ideal for sharp corners and complex features in plastic injection mould making.

EDM Wire Cutting

High-precision EDM wire cutting with 0.25mm brass wire delivers intricate, accurate cuts, perfect for producing detailed dies and punches used in metal press tooling and fabrication.

Surface Grinding

Achieve perfect flatness with our surface grinding service, which provides up to 0.01mm accuracy on steel components using magnetic clamping and expert grinding techniques for precise finishes.

Conventional Turning

Our manual turning service offers custom, one-off parts made by skilled operators who ensure precision through expert cutting, careful measurement, and hands-on craftsmanship for reliable results.

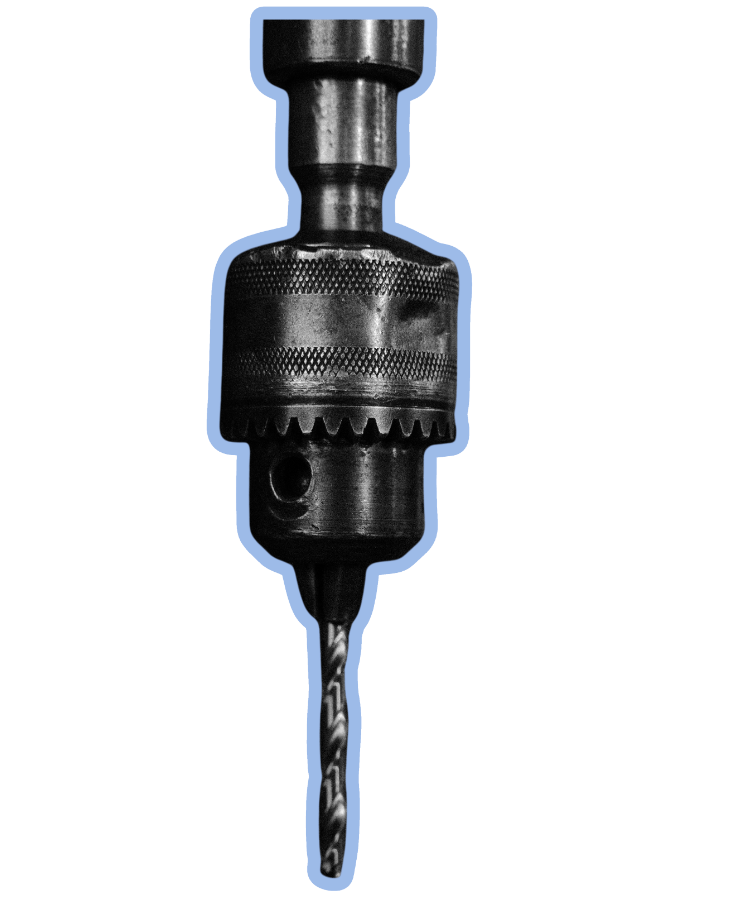

Conventional Milling

Efficient manual milling for drilling, slot cutting, and basic engineering tasks. Our experienced artisans handle straightforward projects with precision, delivering consistent quality in each custom component.

Cam Auto Turning

We utilize 17 cam auto lathes for high-volume production of simple round parts, ensuring consistent, repeatable quality with efficient automated machining for rapid turnaround times.

Metal Press Tooling

From design to production, our metal press tooling services deliver quality parts with precision. We fabricate dependable dies for efficient and accurate metal stamping processes.

Metal Press Tooling In Boksburg

What They say about Paxprecision

Briefing

Gathering project details to understand your exact requirements.

Processing

Expert machining for precise, high-quality component creation.

Finishing

Final inspection and finishing for flawless product delivery.

The Process For Exceptional Results

At Paxprecision, we follow a clear, efficient process to ensure every project meets our high standards. From initial planning to final delivery, we focus on precision, quality, and timely execution.

Our step-by-step approach ensures seamless collaboration and efficient project delivery. With clear communication and precise execution at every stage, we guarantee a smooth process from start to finish, tailored to meet your exact needs.

Your Questiones, Answered.

We specialize in CNC milling, CNC turning, EDM spark eroding, wire cutting, surface grinding, conventional machining, and metal press tooling for a wide range of applications.

Currently, we operate from our fully equipped facility, ensuring high precision and efficiency. However, we can assist with tool repairs at our factory.

Yes, our team consists of highly skilled professionals with over 20 years of industry experience, all certified in their respective fields.

We adhere to strict industry standards, using advanced machinery and thorough inspection processes to guarantee precision and safety in every project.

We work with a variety of materials, including steel, aluminium, brass, copper, and certain plastics, depending on your project’s requirements.

Pricing is based on material selection, complexity, and project scope. We offer a detailed quote after reviewing your specifications and requirements.

Hours of Expertise

Satisfied Clients

Skilled Welders

Metal Press Tooling In Boksburg

Paxprecision (Pty) Ltd offers top-tier metal press tooling in Boksburg. With over 20 years of experience, we deliver high-quality engineering solutions and precise manufacturing capabilities.

Let’s Discuss Your Next Project

Ready to take your engineering project to the next level? Get in touch with Paxprecision today. Our team is here to answer your questions, provide detailed quotes, and help you achieve the precision and quality you need.

Phone

083 738 3939

paxprecision@outlook.co.za

Address

Unit 2 & 9, 22 Brakpan Rd, Boksburg East Industrial, Boksburg.